While aggregate is typically perceived as passive filler, it constitutes 60 to 80 percent of the volume and 70 to 85 percent of the weight in concrete. Despite its inert nature, aggregate is an essential constituent that determines concrete’s thermal and elastic characteristics as well as dimensional stability.

Value of aggregate gradation for concrete slab

Aggregates, inert granular materials like sand, gravel, or crushed stone, are a vital component in concrete when combined with water and Portland cement.

Aggregate can be categorized into two main types: coarse and fine. Coarse aggregate typically consists of particles greater than 4.75 mm (retained on a No. 4 sieve), while fine aggregate comprises particles smaller than 4.75 mm (passing through the No. 4 sieve). In the context of normal concrete strength, the compressive strength of most concrete aggregates significantly exceeds that of other concrete components and does not typically influence concrete strength. However, in lightweight aggregate concrete, the compressive strength of aggregates may have a more noticeable impact. There is also a third category, Combined Aggregate, discussed in this article.

Before mixing concrete, it is crucial to understand other physical and mineralogical properties of aggregates to create a desirable mixture. These properties encompass shape, texture, size gradation, moisture content, specific gravity, reactivity, soundness, and bulk unit weight. These properties, in conjunction with the water/cementitious material ratio, determine concrete’s strength, workability, and durability.

Properties of aggregate gradation for concrete slab

The shape and texture of aggregate have a more pronounced impact on the properties of fresh concrete rather than on hardened concrete. The use of smooth and rounded aggregates enhances the workability of concrete in contrast to rough, angular, or elongated aggregates. Natural sands and gravels typically sourced from riverbeds or seashores are often smooth and rounded, making them excellent choices for aggregates. On the other hand, crushed stone yields angular and elongated aggregates with a higher surface-to-volume ratio, providing better bonding characteristics but necessitating more cement paste to achieve workability.

Aggregate surface texture can be either smooth or rough. A smoother surface contributes to improved workability, while a rougher surface fosters a stronger bond between the paste and the aggregate, resulting in higher strength.

Moisture content within aggregates is a critical factor when determining the appropriate water-to-cementitious material ratio. All aggregates retain some level of moisture due to particle porosity and storage conditions. Moisture content can range from less than one percent in gravel to as high as 40 percent in very porous materials like sandstone and expanded shale. Aggregates exist in four distinct moisture states: oven-dry (OD), air-dry (AD), saturated-surface dry (SSD), and wet. Among these, only OD and SSD represent specific moisture states and serve as reference points for calculating moisture content. To determine the water quantity that aggregates will either contribute or absorb from the paste, one must calculate three key factors: absorption capacity, effective absorption, and surface moisture.

Typically, stockpiled coarse aggregate is in the AD state with an absorption rate of less than one percent, while fine aggregate often exists in the wet state with surface moisture of up to five percent. The surface moisture on fine aggregate forms a thick film over the particles, causing them to separate and increasing their apparent volume. This is commonly referred to as “bulking” and can lead to substantial errors in volume proportioning.

Density of the aggregate gradation for concrete slab

In mixture proportioning, the density of aggregates is essential for establishing weight-volume relationships. Specific gravity can be readily determined by measuring densities through water displacement. All aggregates possess some level of porosity, and the specific gravity value depends on whether these pores are factored into the measurement. Two terms are used to differentiate this measurement: absolute specific gravity (ASG) and bulk specific gravity (BSG), sometimes referred to as apparent specific gravity. ASG pertains to the solid material, excluding the pores, while BSG includes the volume of the pores. When it comes to mixture proportioning, understanding the space occupied by aggregate particles, encompassing the pores within those particles, is crucial. The specification of BSG is often conducted to meet minimum density requirements, although BSG itself is not directly linked to aggregate performance in concrete.

For mixture proportioning, the determination of bulk unit weight, also known as bulk density, is imperative. Bulk density quantifies the volume that the graded aggregate will occupy in concrete, encompassing both the solid aggregate particles and the void spaces between them. Maintaining a consistent moisture content in the aggregate is essential since the weight of the aggregate is contingent on its moisture content. This consistency is typically achieved by using oven-dry (OD) aggregate. Furthermore, bulk density is necessary for the volume-based method of mixture proportioning.

Classification of aggregate gradation for concrete slab

Aggregates are commonly classified based on bulk specific gravity into lightweight, normal-weight, and heavyweight categories. In typical concrete, the aggregate weighs between 1,520 and 1,680 kg/m³. However, specific design requirements may call for either lightweight or heavyweight concrete. Lightweight concrete employs aggregates, whether natural or synthetic, that weigh less than 1,100 kg/m³, while heavyweight concrete uses aggregates, whether natural or synthetic, that exceed 2,080 kg/m³ in weight.

Despite the prevailing notion of aggregates as inert fillers in concrete, their distinct properties exert a substantial influence on concrete’s strength, durability, workability, and cost-effectiveness. These diverse aggregate properties afford designers and contractors the flexibility to tailor concrete mixes to meet their design and construction needs.

Aggregates for cement concrete flooring mixes must adhere to the specifications outlined in IS: 383-1963. The aggregate crushing value, as determined in accordance with IS: 2386 (Part IV)-1963, should not exceed 30 percent. The grading of coarse aggregate for cement concrete flooring mixes should generally fall within the following size ranges:

a) For base concrete (lean cement or lime concrete), graded from 40 mm and below.

b) For cement concrete topping with a thickness of 40 mm and above, graded from 16 mm and below.

c) For cement concrete topping with a thickness of 25 mm.

Importance of aggregate gradation for concrete slab

To achieve a high-quality concrete mix, aggregates must meet specific criteria. They should be clean, possess hardness, and consist of robust particles free from absorbed chemicals or coatings such as clay and fine materials that could potentially harm the concrete’s long-term integrity. Aggregates, which make up 60 to 75 percent of the total concrete volume, can be categorized into two distinct groups: fine and coarse. Fine aggregates typically comprise natural sand or crushed stone, with the majority of particles passing through a 3/8-inch sieve. Coarse aggregates encompass particles larger than 0.19 inches, generally falling within the range of 3/8 to 1.5 inches in diameter. Gravel constitutes the primary source of coarse aggregate in concrete, with crushed stone comprising the remainder.

Aggregates exert a significant influence on the freshly mixed and hardened properties of concrete, as well as on mixture proportions and overall cost-effectiveness. Consequently, the selection of aggregates is a critical process.

Grading involves the assessment of the particle-size distribution of aggregates. Grading limits and the maximum aggregate size are specified because these factors impact the amount of aggregate, as well as the requirements for cement and water. They also affect workability, pumpability, and the durability of concrete. Generally, when the water-cement ratio is chosen correctly, a wide range in grading can be used without significantly affecting the concrete’s strength. In cases where gap-graded aggregates are specified, certain particle sizes are intentionally excluded from the size range. Gap-graded aggregates are employed to achieve consistent textures in exposed aggregate concrete. Careful control of mix proportions is essential to prevent segregation.

Different types of aggregate gradation specification for concrete slab

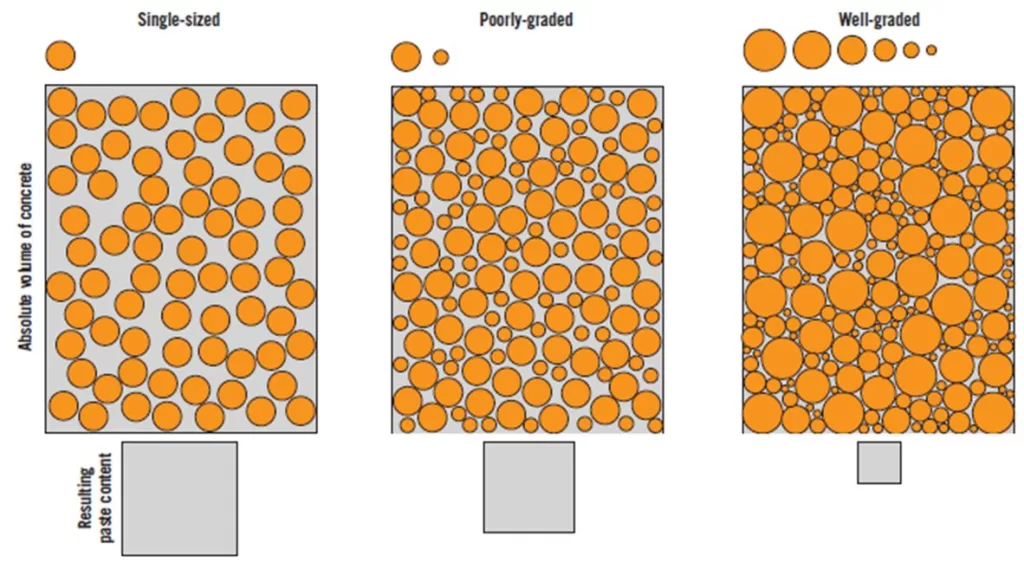

The grading or size distribution of aggregates holds significant importance as it directly influences the paste needed to create workable concrete. This paste requirement plays a crucial role in determining the overall cost of the concrete mix, given that cement stands out as the most expensive component. Consequently, it is advantageous to minimize the quantity of paste while still ensuring the production of concrete that can be easily managed, compacted, and finished, while meeting the requisite strength and durability standards.

The amount of cement paste required depends on two key factors: the void space that must be filled and the total surface area that needs to be covered. When the aggregate particles are of uniform size, they create the largest void spaces, but when a range of particle sizes is introduced, these voids get filled, reducing the demand for paste. As these voids are increasingly filled, the workability of the concrete diminishes. Therefore, a balance between workability and cost-effectiveness becomes essential.

Fine-Aggregate Grading

The grading requirements outlined in ASTM C 33 or AASHTO M 6/M 43 standards permit a relatively broad range in fine-aggregate gradation. Nevertheless, specifications from other organizations may sometimes impose more stringent criteria. The most suitable fine-aggregate grading depends on the specific project, the mix’s richness, and the maximum size of the coarse aggregate. In scenarios involving leaner mixtures or when smaller coarse aggregates are employed, a grading approach that aligns with the maximum recommended percentage passing through each sieve is preferable for workability. In general, as long as the water-cement ratio remains constant and the fine-to-coarse aggregate ratio is chosen appropriately, a wide range in grading can be used without significantly affecting the concrete’s strength. However, optimizing the concrete mixture to match the local aggregate gradation may sometimes lead to the most cost-effective solution.

For most concrete applications, fine-aggregate grading within the limits of ASTM C 33 (AASHTO M 6) is typically suitable. The ASTM C 33 (AASHTO M 6) standards specify limits concerning sieve sizes.

AASHTO specifications permit the minimum percentages (by mass) of material passing the 300 µm (No. 50) and 150 µm (No. 100) sieves to be reduced to 5% and 0%, respectively, under specific conditions, including the use of air-entrained concrete, non-air-entrained concrete, or supplementary cementitious materials to compensate for the deficiency.

Other requirements of ASTM C 33 (AASHTO M 6) include:

- Ensuring that the fine aggregate does not have more than 45% retained between any two consecutive standard sieves.

- Maintaining a fineness modulus that falls between 2.3 and 3.1 and does not deviate more than 0.2 from the typical value of the aggregate source. If this limit is exceeded, adjustments in fine and coarse aggregate proportions are necessary.

The percentage of fine aggregate passing the 300 µm (No. 50) and 150 µm (No. 100) sieves significantly influences workability, surface texture, air content, and bleeding in concrete. Most specifications allow for a range of 5% to 30% passing the 300 µm (No. 50) sieve. The lower limit may suffice for straightforward placement conditions or mechanically finished concrete, as seen in pavements. However, for hand-finished concrete floors or when a smooth surface texture is desired, it’s advisable to use fine aggregate with at least 15% passing the 300 µm (No. 50) sieve and 3% or more passing the 150 µm (No. 100) sieve.

Coarse-Aggregate Grading

ASTM C 33 (AASHTO M 80) provides relatively wide latitude for coarse aggregate grading requirements, allowing for a range of sizes. The grading of coarse aggregate can be adjusted within a moderate range for a specific maximum-size coarse aggregate without significantly impacting the cement and water requirements, provided that the proportion of fine aggregate to total aggregate still results in workable concrete. However, if substantial variations in coarse-aggregate grading arise, it’s advisable to modify the mixture proportions to ensure workability. Since predicting variations can be challenging, it is often more cost-effective to maintain consistency in the production and handling of coarse aggregate than to try and minimize variations in gradation.

The choice of the maximum size of coarse aggregate in concrete has economic implications. Smaller-size aggregates generally require more water and cement due to the increase in total aggregate surface area. When striving for a slump of approximately 75 mm (3 in.) with various coarse-aggregate sizes, the amount of cement required decreases as the maximum size of coarse aggregate increases. However, the increased cost associated with obtaining and handling larger aggregates, particularly those exceeding 50 mm, may offset the savings from using less cement. Additionally, aggregates with different maximum sizes can result in slightly varying concrete strengths at the same water-cement ratio. In certain cases, concrete with a smaller maximum-size aggregate may exhibit higher compressive strength, particularly with high-strength concrete. The ideal maximum size of coarse aggregate for achieving greater strength depends on factors such as the relative strength of the cement paste, the bond between cement and aggregate, and the strength of the aggregate particles.

It is important to use precise terminology when specifying the size of coarse aggregate. Particle size is determined by the size of the sieve, and it applies to the aggregate that passes through that sieve while not passing the next smaller sieve. When discussing a range of particle sizes, the size number or grading size of the gradation is employed. The size number corresponds to the total quantity of aggregate that passes through a set of sieves.

Combined Aggregate Grading

In the analysis of aggregates, it is sometimes beneficial to consider the combined grading of both fine and coarse aggregates as they coexist in a concrete mixture. This approach offers a more comprehensive evaluation of how aggregates will perform within concrete. Occasionally, there may be a scarcity of mid-sized aggregates, typically around 9.5 mm (3⁄8 in.), in the available aggregate supply. This shortage can lead to concrete with undesirable characteristics, including high shrinkage, increased water demand, reduced workability, poor pumpability, and difficult placement. Such issues can have a detrimental impact on the concrete’s strength and durability. Although achieving a perfect gradation in the field may be challenging, striving to approximate it is worthwhile. When problems arise due to inadequate gradation, it’s advisable to explore solutions such as alternative aggregates, blending different aggregate sources, or employing specialized screening techniques on existing aggregates.

Using combined gradation allows for better control over concrete properties such as workability, pumpability, shrinkage, and others, contributing to improved overall concrete performance.

- With a consistent cement content and uniform consistency, there exists an optimal combination of aggregates that achieves the most favorable water-to-cement ratio and highest strength.

- This ideal mixture experiences minimal particle interference and demonstrates superior responsiveness to a high-frequency, high-amplitude vibrator.

Conclusion

In the process of concrete mix design, the targeted strength is typically considerably lower than the compressive strength of the aggregates utilized in the mix. This relationship is evident in the mix design procedure, where it’s observed that a larger maximum size of coarse aggregate leads to a reduced cement requirement to reach the desired strength. Therefore, it’s evident that a greater maximum size of aggregate contributes to a higher compressive strength in the resulting concrete.