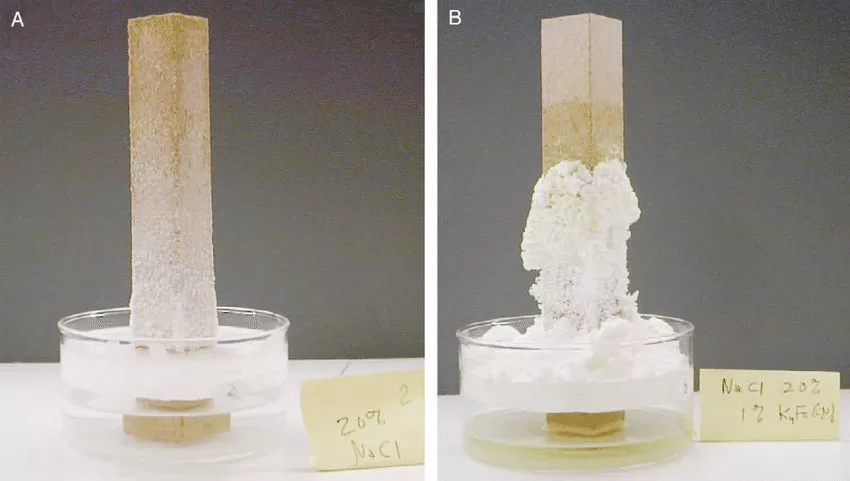

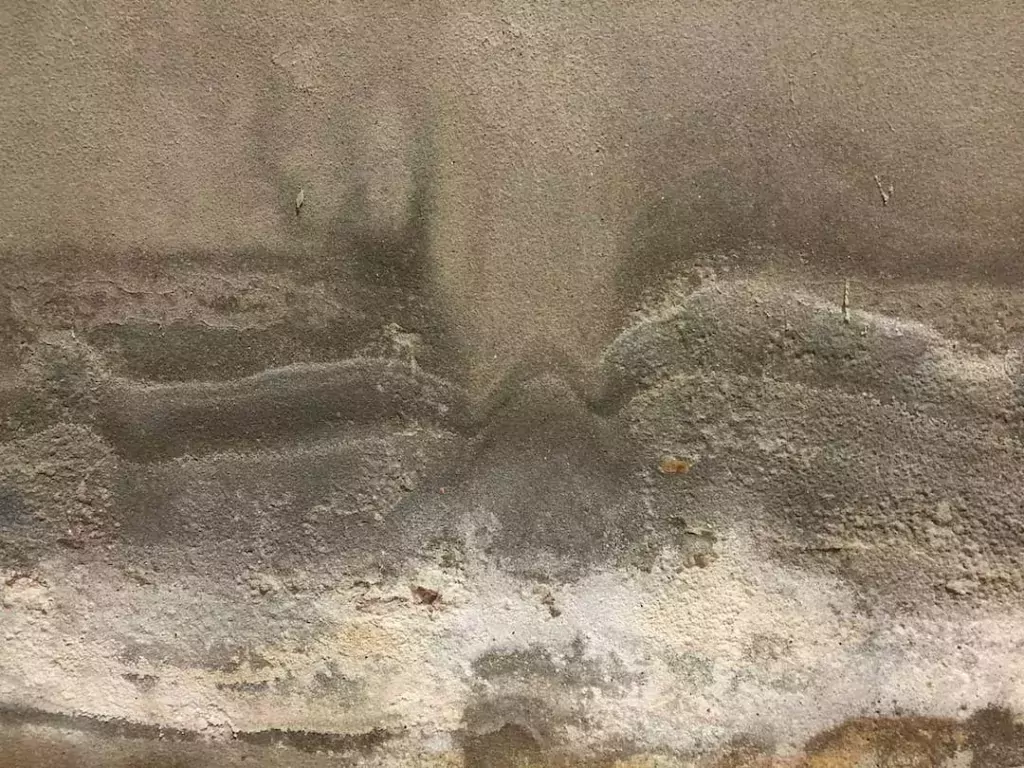

Efflorescence in concrete manifests as a white powdery substance on unsealed concrete surfaces and as a white blush on sealed floors. It occurs when vapor permeates through the concrete, carrying soluble salts to the surface.

Typically, efflorescence naturally wears off or is washed away on unsealed concrete. In persistent cases, a mild acid rinse or light sandblasting may be required. However, when efflorescence becomes trapped under a sealer, especially on darker floors, it becomes noticeably unsightly.

WHY EFFLORESCENCE IN CONCRETE HAPPENS?

Efflorescence in concrete floor is the outcome of water-soluble salts making their way to the surface of concrete. These mineral salts may arise from the cement hydration reaction or various sources, such as sulphate-rich sand. The susceptibility of porous concretes, masonry, and mortars to salt migration to the surface is heightened. Additionally, a higher concentration of mineral salts in the concrete increases the likelihood of efflorescence.

As salt-rich water migrates to the surface, the water evaporates, leaving behind salt deposits that manifest as the characteristic white staining on the surface. Understanding these factors is crucial in addressing and managing efflorescence-related issues in concrete structures.

8 Type of salts in Efflorescence on concrete Floor

Efflorescence in concrete floor can arise from various salts, each contributing to distinctive characteristics:

- Calcium Sulphate:

- Frequently observed in brick, serving as a common source of efflorescence.

- Sodium Sulphate:

- Often encountered in reactions involving cement and brick.

- Potassium Sulphate:

- Evident in numerous cement-brick interactions.

- Calcium Carbonate:

- Found in mortar or concrete backing, contributing to efflorescence.

- Sodium Carbonate:

- Commonly identified in mortar applications.

- Potassium Carbonate:

- Similar to sodium carbonate, often present in mortar compositions.

- Vanadyl Sulphate:

- Typically found in brick structures.

- Manganese Oxide:

- Frequently present in bricks, contributing to efflorescence.

Prevent Efflorescence in concrete floor with 13 Proven ways

Efflorescence can be effectively minimized through a combination of strategic measures during concrete installation and mix design. Key practices include:

- Site Surface Drainage:

- Ensure proper drainage on the site surface to prevent the accumulation of water to get rid of white marks on concrete.

- Well-Graded Concrete Mix:

- Utilize a well-graded concrete mix with a water reducer to minimize paste, aiming for a concrete not exceeding a 4″ slump.

- Concrete Consolidation:

- Thoroughly consolidate the concrete, employing effective methods such as vibratory screeds.

- Vapor Retarder:

- Place the concrete directly on a vapor retarder to impede moisture migration.

- Curing:

- Implement a comprehensive curing process to promote denser and less permeable concrete. This involves keeping the concrete moist for an extended period, especially in the initial days.

- Waterproofing Admixture:

- Consider using a waterproofing admixture in the concrete mix to prevent efflorescence in concrete floor. However, be cautious as it may affect the acceptance of acid or water-based stains.

- Surface Preparation for Staining:

- In cases where a waterproofing admixture is used, prepare the surface for staining by employing methods such as sanding or applying a gelled acid to create a suitable profile.

- Mix Design Factors:

- Request a well-graded mix from the ready-mix producer to reduce the weakest part of concrete, the cement paste, resulting in denser concrete. Additionally, replacing a portion of Portland cement with fly ash significantly contributes to efflorescence reduction.

- Fly Ash Benefits:

- Fly ash diminishes Portland cement and free lime content while chemically binding up a portion of free lime and salts causing efflorescence. It requires less water, contributing to a denser paste and hindering moisture movement.

- Water Reducers:

- Implement water reducers to minimize water content and reduce cement paste.

- Water-Cement Ratio:

- For removing Efforescence in concrete floor, aim for a water-cement ratio close to 0.45 pounds of water to pounds of cement, especially with a mix containing fly ash, to mitigate efflorescence issues.

- Cold Weather Considerations:

- Follow ACI 306 Cold-Weather Concreting procedures, ensuring concrete placement at a temperature of 60 degrees and covering overnight to encourage a denser pore and capillary structure.

- Curing Practices:

- Opt for continuous wet curing to slow down moisture movement and consider compatible curing membranes for subsequent staining, as some membranes may need removal.

By combining these measures, concrete installations can significantly reduce the occurrence of efflorescence and promote the creation of a dense, impermeable matrix.

BEST ways to get rid of white marks on concrete

When faced with efflorescence in concrete issues, there are several options to address the problem, each with its considerations:

- Quick Fix with Solvent-Based Products:

- A fast solution involves using toluene, xylene, or another coat of solvent-based acrylic to reemulsify the original sealer and clear those dirty white marks on concrete. However, this is a temporary fix, and if vapor continues to rise through the slab, the issue may reappear. Note that using solvents can pose health risks, especially in occupied spaces.

- Stripping and Remedial Strategy:

- The more prudent approach is to strip the sealer and conduct tests to determine the rate of vapor transfer. Investing in handheld digital instruments can provide accurate moisture readings below the surface. Once moisture levels are established, choose a sealer based on the manufacturer’s recommendations.

- Vapor Inhibiting Sealers:

- Some manufacturers offer vapor inhibiting, non-film forming sealers that reduce vapor transmission rates. These can be used as a base coat, allowing for the application of heavier, abrasion-resistant top coats in high-traffic areas.

- Alternative Treatments:

- In cases where efflorescence in concrete persists even after using densifiers like lithium or silicate, contractors have turned to industrial-grade finishes or polishes. These low-build, low-solids micronized acrylic water-based products provide a final treatment, adding abrasion resistance. They can also be applied over film-forming sealers.

- Thorough Diagnosis:

- Diagnosing efflorescence causes after sealing can be challenging. It is crucial to determine the moisture content in the slab, identify the moisture source, and assess potential future contributors like seasonal groundwater. Utilizing vapor testing and resisting quick fixes is essential.

- Contractual Considerations:

- Contractors may choose to avoid warranty language related to sealers or may explicitly define typical vapor transmission problems in contracts. The adage “test, test, and test” holds true, emphasizing the importance of conducting Vapor Transmission Rate (VTR) tests whenever efflorescence problems are suspected. It’s crucial to prioritize thorough testing and assessment before proceeding.

CONCLUSION: Efflorescence in concrete floor

Efflorescence in concrete floor challenges demand a thoughtful, systematic approach. While quick fixes exist, comprehensive measures such as stripping, testing, and considering alternative treatments provide more sustainable solutions. Thorough diagnosis, strategic material choices, and contractual clarity contribute to successful efflorescence management in decorative concrete projects.