Concrete, renowned for its durability and adaptability in construction, finds extensive use in various applications, such as sewage systems, tunnels, storage tanks, roads, bridges, building façades, industrial floors, and sidewalks. Despite its resilience, concrete faces challenges in high-traffic areas and harsh environments, leading to material degradation, staining, and microbial contamination. Of particular concern is microbially induced corrosion (MIC), a significant issue in industries relying on concrete. MIC poses a threat to the structural integrity of concrete structures, necessitating costly cleaning and maintenance efforts.

Microbially induced concrete corrosion refers to the accelerated degradation of concrete caused or facilitated by microorganisms. Concrete, being inherently porous, undergoes natural degradation over time. MIC expedites this process by generating acids through microbial activities. These acids react with concrete ingredients, diminishing its stability and ultimately resulting in premature structural failure.

Freshly produced concrete boasts a high pH value, making it alkaline and inhibiting the growth of most microbes. However, certain microbes thrive in high-alkaline environments and initiate biodeterioration upon reaching the concrete surface. Bacteria and mold are examples of microorganisms contributing to this deterioration.

As alkaline-friendly microbes proliferate, they oxidize sulphates, producing sulphuric acid—a highly corrosive substance that damages the concrete. The formation of sulphuric acid also shifts the pH to a more conducive level for other microbes, allowing their survival and reproduction on the concrete surface. Once contamination occurs, the growth of microbes continues, generating biogenic acids and causing further deterioration. Microbially induced corrosion of concrete seldom results from a single microbe; rather, it involves a complex ecosystem that creates conditions favoring the introduction of additional microorganisms. Regular decontamination with potent disinfectants is crucial to mitigate the impact of MIC on concrete surfaces.

Causes of microbial corrosion in construction

Causes of microbial corrosion in construction can be attributed to the actions of microorganisms, including bacteria, fungi, and algae. Several key factors contribute to this corrosion:

- Microbial Metabolism: Microorganisms have the capability to metabolize chemicals found in construction materials, generating corrosive byproducts that can harm the structural integrity of the materials.

- Moisture and Oxygen Availability: Microbial corrosion tends to flourish in environments characterized by high moisture levels and ample oxygen availability. Construction materials exposed to such conditions become more prone to microbial attacks.

- Microbial Biofilms: The formation of biofilms by microorganisms on the surface of construction materials creates a protective environment that fosters corrosion, providing a conducive habitat for microbial activity.

- Chemical Secretions: Certain microorganisms release corrosive substances as metabolic byproducts, hastening the degradation of construction materials through their chemical activities.

- Electrochemical Reactions: Microbes can engage in electrochemical reactions that amplify the corrosion of metals, particularly in the presence of water and dissolved ions.

- Nutrient Availability: Microorganisms require nutrients for their growth. Construction materials containing organic components can serve as a nutrient source, attracting microbial activity and contributing to the corrosion process.

- pH Changes: Microbial activities can lead to alterations in the pH of the surrounding environment, creating conditions conducive to the corrosion of specific construction materials.

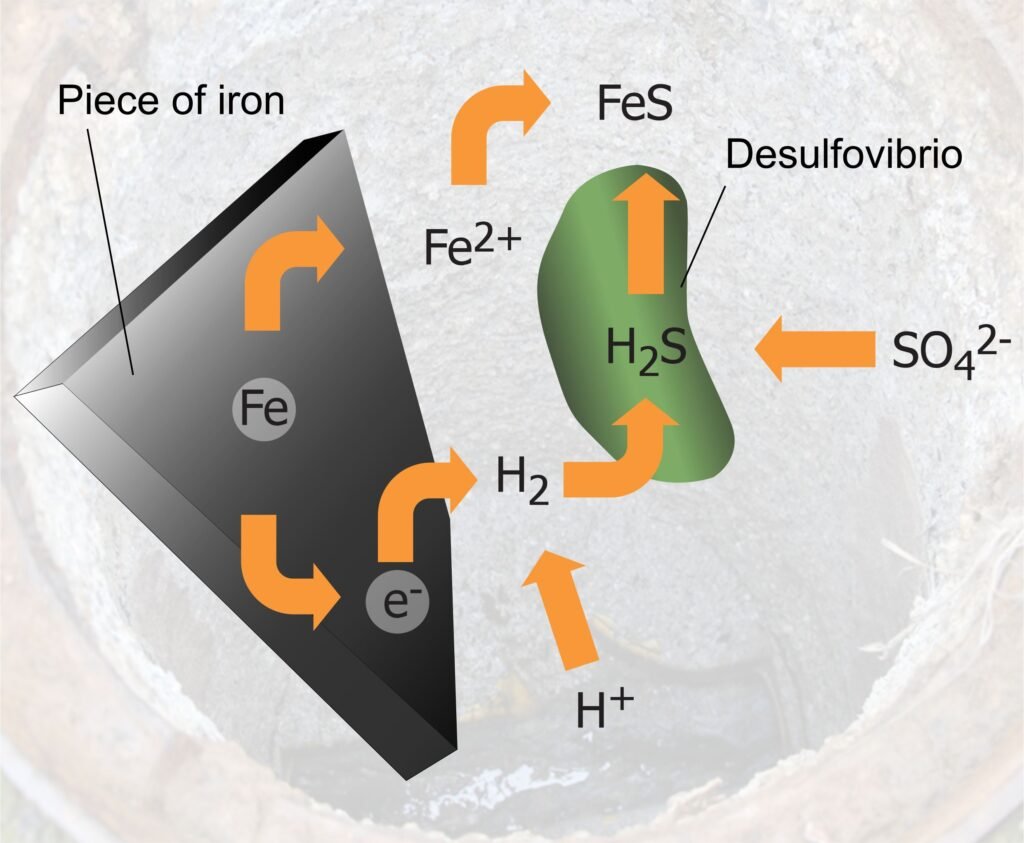

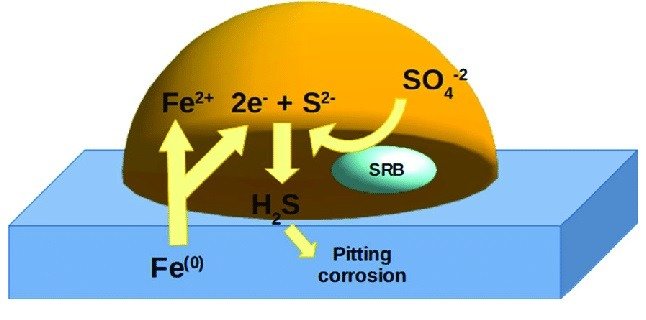

- Sulfate-Reducing Bacteria (SRB): SRB are recognized for producing hydrogen sulfide gas during their metabolic processes, leading to sulfide stress corrosion cracking in metals.

- Microbial Interaction with Coatings: Microorganisms can compromise protective coatings on construction materials, rendering them more vulnerable to corrosion and undermining their ability to resist environmental degradation.

Types of Microbial Corrosion

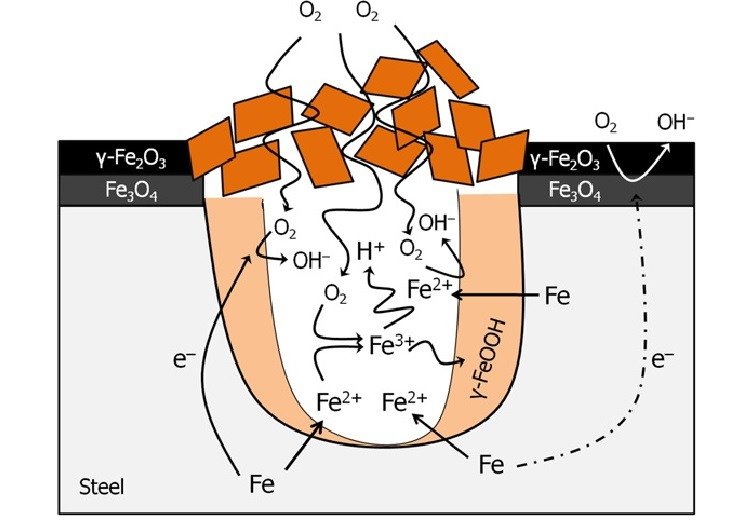

Aerobic Corrosion:

Aerobic corrosion is initiated by oxygen-dependent microorganisms, like Pseudomonas aeruginosa. These bacteria consume organic matter in construction materials, utilizing oxygen for metabolic activities and contributing to material degradation.

Anaerobic Corrosion:

In low-oxygen environments, anaerobic corrosion prevails. Microbes, such as Desulfovibrio bacteria, produce corrosive byproducts like organic acids and hydrogen sulfide, accelerating material corrosion, especially in soil or waterlogged areas.

Sulfate-Reducing Bacteria (SRB) Corrosion:

Driven by bacteria metabolizing sulfates, SRB corrosion generates corrosive hydrogen sulfide gas. Bacteria like Desulfotomaculum contribute to sulfide-induced corrosion, affecting structures in sulfate-rich environments, such as buried pipelines.

Iron Bacteria Corrosion:

Iron bacteria, like Gallionella, induce iron-related corrosion by oxidizing iron, leading to rust formation. Encountered in water systems, these bacteria pose a challenge to structures with iron or steel components.

Acid-Producing Bacteria Corrosion:

Acid-producing bacteria, exemplified by Thiobacillus, create acidic conditions by oxidizing sulfur and producing sulfuric acid. This corrosion is a concern in environments with sulfur-containing compounds, affecting steel and concrete structures.

Where Microbial Corrosion Occurs:

- Underground Pipelines: Metal pipelines buried underground are susceptible to microbial corrosion, causing deterioration and potential leakage.

- Marine Structures: Structures in contact with seawater, like piers and offshore platforms, are prone to microbial corrosion due to aggressive marine microorganisms.

- Sewer Systems: Microbial activity in sewage environments can contribute to pipe and structure corrosion, especially with the presence of sulfate-reducing bacteria.

- Biogas Plants: Microbial corrosion can impact structures and pipes in anaerobic environments like biogas digesters, affecting their integrity.

- Concrete Structures: Environments with high moisture and organic content can lead to microbial corrosion in concrete, degrading reinforcing steel.

- Water Treatment Facilities: Water treatment plants may face microbial-induced corrosion, affecting metal components’ durability.

- Cooling Systems: Microbial corrosion can occur in cooling water systems, impacting heat exchangers and other metal components.

Mitigation Strategies:

- Material Selection: Choose corrosion-resistant materials like stainless steel or treated wood.

- Moisture Control: Minimize water exposure through proper waterproofing and drainage.

- Ventilation: Ensure adequate ventilation to reduce humidity levels, inhibiting microbial growth.

- Surface Coatings: Apply antimicrobial coatings to materials to inhibit microbial growth and protect surfaces.

- Regular Inspections: Conduct regular inspections to identify and address signs of microbial corrosion early on.

- Cleaning and Maintenance: Keep surfaces clean to prevent the buildup of organic matter that microbes feed on.

- pH Control: Maintain appropriate pH levels, as some microbes thrive in specific pH conditions.

- Cathodic Protection: Implement cathodic protection systems to safeguard metals from microbial-induced corrosion, using methods like sacrificial anodes or impressed current systems.

Conclusion

Microbial corrosion poses a significant threat to various structures, ranging from underground pipelines to marine installations, sewer systems, and beyond. Understanding the different types of microbial corrosion, such as aerobic, anaerobic, sulfate-reducing bacteria (SRB), iron bacteria, and acid-producing bacteria corrosion, is crucial for implementing effective mitigation strategies.