A collaborative effort between researchers at MIT and the Institute of Science and Technology Austria has yielded a groundbreaking technique. This method allows for the integration of a wide array of building blocks used in cellular metamaterials into a cohesive and unified graph-based representation. This innovation serves as the foundation for a user-friendly interface designed to empower engineers, enabling them to efficiently model metamaterials, make real-time structural adjustments, and simulate the various properties of these complex materials.

The resulting platform promises to streamline the process of working with metamaterials, making it more accessible and practical for engineers and researchers. Additionally, it is anticipated to have a significant impact on the development and application of metamaterials in various fields, thanks to its versatility and user-friendliness.

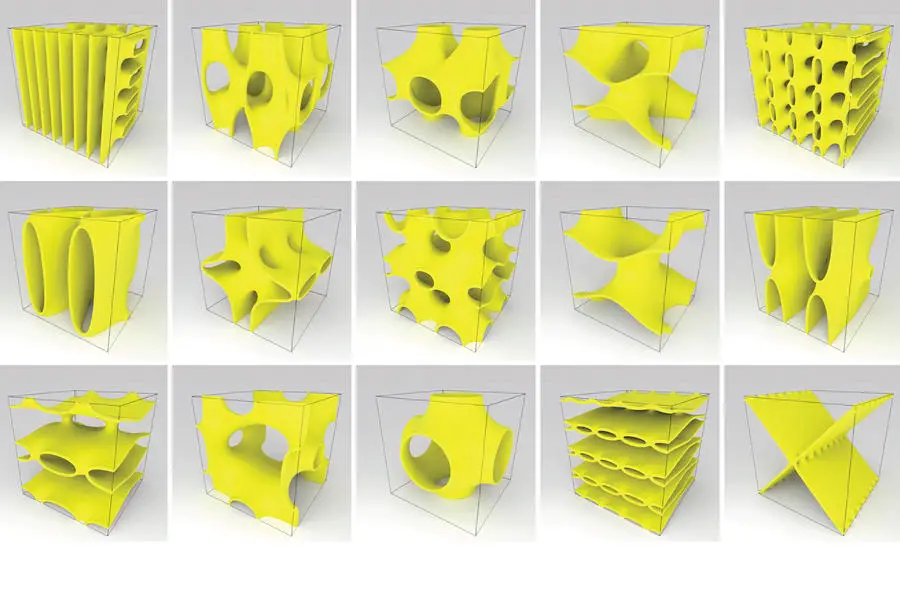

The introduction of a user-friendly interface now enables researchers to swiftly craft a myriad of cellular metamaterial structures boasting distinct mechanical properties.

In the quest for materials boasting novel and sought-after properties, engineers perpetually seek innovative solutions. One example is the pursuit of ultra-strong, lightweight materials for enhancing the fuel efficiency of airplanes and cars. Conversely, there’s also a need for porous, biomechanically-friendly materials suitable for bone implants.

Cellular metamaterials, which are man-made structures comprising repeating units or cells arranged in various patterns, offer the potential to meet these objectives. However, identifying the precise cellular structure that will yield the desired properties can be a formidable challenge. Even when considering structures constructed from smaller building blocks such as interconnected beams or thin plates, the number of possible arrangements is virtually limitless. Consequently, engineers can only manually explore a minute fraction of the theoretically possible cellular metamaterials.

A breakthrough computational technique has been devised by researchers from MIT and the Institute of Science and Technology Austria. This innovation simplifies the process of designing a metamaterial cell from a variety of smaller building blocks and subsequently assessing the properties of the resulting metamaterial.

In a methodology resembling a specialized CAD (Computer-Aided Design) system tailored for metamaterials, engineers can now rapidly model intricate metamaterials and experiment with designs that would typically require days to develop. This user-friendly interface also empowers users to explore the entire spectrum of potential metamaterial shapes, as it provides access to all available building blocks.

According to Liane Makatura, co-lead author of the paper detailing this technique and a graduate student in MIT’s electrical engineering and computer science department, “We’ve devised a representation that encompasses all the various shapes engineers have conventionally found interesting. Because they can all be constructed in the same manner, this facilitates seamless transitions between them.”

Makatura collaborated with co-lead author Bohan Wang, an MIT postdoctoral researcher, along with Yi-Lu Chen, a graduate student at the Institute of Science and Technology Austria (ISTA); Bolei Deng, another MIT postdoc; and the expertise of professors Chris Wojtan and Bernd Bickel from ISTA. The senior author of this research is Wojciech Matusik, a professor of electrical engineering and computer science at MIT, leading the Computational Design and Fabrication Group within the MIT Computer Science and Artificial Intelligence Laboratory. This research is scheduled to be presented at SIGGRAPH.

Traditionally, when a scientist embarks on developing a cellular metamaterial, they first select a representation that will serve as the basis for describing their potential designs. This choice dictates the range of shapes they can explore.

For example, one might opt for a technique that characterizes metamaterials using interconnected beams, but this choice may restrict exploration of metamaterials based on other elements, like thin plates or 3D structures such as spheres. Different representations offer access to these various shapes, but, up until now, there hasn’t been a unified method to encompass all shapes within a single approach.

Makatura emphasizes the potential pitfalls of choosing a specific subspace at the outset, as it can limit exploration and introduce biases based on intuition. She notes, “While intuition can be valuable, it can also be fallible, and there may be other shapes worth exploring for a given application.”

In their analysis of various metamaterials, Makatura and her team recognized that the complex shapes forming the overall structure could be effectively represented by lower-dimensional shapes. For instance, a beam could be simplified to a line, or a thin shell could be compressed into a flat surface.

Furthermore, they observed that cellular metamaterials often exhibit symmetries, meaning that only a small portion of the structure needs to be represented. The remaining parts can be generated through rotation and mirroring of the initial piece.

Makatura further elaborates, “By combining these two insights, we arrived at the concept that cellular metamaterials could be aptly represented as a graph structure.”

In this graph-based representation, users construct a metamaterial skeleton by utilizing building blocks generated by vertices and edges. For instance, to create a beam structure, one would place a vertex at each endpoint of the beam and connect them using a line.

Subsequently, the user can apply a function to that line, specifying the desired thickness of the beam, with the flexibility to vary the thickness along its length.

The approach for surfaces follows a similar pattern. The user designates key features using vertices and then selects a solver that can deduce the remaining aspects of the surface.

What sets these user-friendly solvers apart is their capacity to expedite the creation of highly intricate metamaterials, including the challenging triply periodic minimal surface (TPMS). Traditionally, developing TPMS structures has been a laborious and failure-prone process.

Makatura explains, “With our representation, you can also start combining these shapes. For example, a unit cell that incorporates both a TPMS structure and a beam structure could yield fascinating properties. Yet, thus far, such combinations have remained largely unexplored.”

Upon completing the process, the system provides a comprehensive graph-based record, encompassing every action the user executed to reach the final structure. This includes all the vertices, edges, solvers, transformations, and thickening operations employed in the metamaterial’s creation.

The user interface empowers designers to preview the evolving structure at any stage in the construction process and predict specific properties, such as stiffness. Designers can iteratively adjust parameters and evaluate the structure until they achieve the desired design.

The researchers applied their system to recreate a wide array of metamaterial structures across different classes. Remarkably, once the skeletons were designed, each metamaterial structure was generated within a matter of seconds.

Furthermore, the researchers developed automated exploration algorithms, endowing each with a set of rules and unleashing them within the system. In one notable test, an algorithm produced over 1,000 potential truss-based structures in approximately an hour.

Furthermore, the researchers conducted a user study involving 10 individuals with limited prior experience in modeling metamaterials. Impressively, the users successfully modeled all six structures they were presented with, and the majority of participants concurred that the procedural graph representation notably simplified the process.

Liane Makatura expresses their satisfaction, stating, “Our representation makes all sorts of structures more accessible to people. We were especially pleased with users’ ability to generate TPMS. These complex structures are usually challenging, even for experts. Surprisingly, one TPMS in our study had the shortest average modeling time among all six structures, which was both surprising and exciting.”

Looking ahead, the researchers aspire to enhance their technique by introducing more intricate skeleton thickening procedures. This will enable the system to model an even broader range of shapes. Additionally, they intend to continue exploring the utilization of automatic generation algorithms.

In the long term, their ultimate goal is to employ this system for inverse design. This approach would involve specifying desired material properties, then utilizing an algorithm to identify the optimal metamaterial structure.

Reference: “Procedural Metamaterials: A Unified Procedural Graph for Metamaterial Design” by Liane Makatura, Bohan Wang, Yi-Lu Chen, Bolei Deng, Chris Wojtan, Bernd Bickel and Wojciech Matusik, 28 July 2023, ACM Transactions on Graphics.

DOI: 10.1145/3605389

Source: scitechdaily.com