Thermal Insulation Materials are used in buildings to limit the heat flow through the building. This improves the cooling or heating of the building while simultaneously saving the heating/cooling cost. There are many different types of materials that are used for thermal insulation. Let us check them out.

What is Thermal Insulation of Buildings?

Thermal insulation is the prevention of heat flow through the buildings. Many areas face severe cold weather, so the residents must keep their homes warm. Consequently, they light up fires inside the house, use a heater, maintain the home temperature by steam, etc.

Furthermore, to make the building heating system work efficiently, it is necessary for the building owners to thermally insulate the building. It keeps the building warm with lesser effort. It is because thermal insulation minimizes the heat escaping from the building.

It should be noted that thermal insulation is also used in hot regions. Their insulation minimizes the flow of outer heat inside the house. So, thermal insulation minimizes the heat flow either from the inner to outer of the building or outer to inner of the building.

Why does Heat Escape from the Building?

When there is a variation in temperature between the exterior and the interior of a building, as well as between the different units within a building, the heat flows from one warm location to a cooler place.

The conduction of heat through solid building materials is the primary mechanism through which heat is transferred. Other methods of heat transfer are convection and radiation. In convection, the heat is transferred by air, whereas the radiation doesn’t need any medium to propagate.

What are Thermal Insulation Materials?

Thermal insulation materials are used to provide thermal insulation to the building. Different materials are available for thermal insulation, such as mineral wool, sawdust, reflective cladding sheets, fiberglass, cellulose, polyurethane foam, polystyrenes, etc.

Insulating materials rely on the inherent molecular makeup of the material to reduce the amount of heat that may be transferred through radiation, conduction, and convection.

Insulation materials with a more dense, self-contained cellular composition will provide a higher thermal resistivity (value) to outperform ‘open cell’ materials, which depend on maintaining dry air within their cores for ultimate performance. Therefore, insulation materials with a higher R-value have a higher thermal resistivity (value).

Types of Thermal Insulation

- Slab or block-insulating materials

- Blanket insulation materials

- Loose-fill insulation materials

- Bat-insulating materials

- Insulating boards

- Reflective sheet materials

- Structural Insulated Panels (SIP)

- Lightweight materials

1. Slab or Block Insulation

Mineral wool, corkboard, cellular glass, cellular rubber, sawdust, etc. used to produce these blocks. These are fixed to the walls and roofs to minimize heat loss and maintain the desired temperature. These planks come in dimensions of 60 by 120 centimeters (or more) and have a thickness of 2.5 centimeters.

2. Blanket Insulation

Insulating blankets are made of flexible fibrous materials like mineral wool, cotton, processed wood fiber, and animal hair. They can be purchased in the form of a blanket or rolls similar to paper.

The installation of blanket insulation is also easy. It can be directly distributed over the wall or ceiling surface and held in place by insulation fasteners. They are bendable, and their thickness ranges from 1 to 8 centimeters.

3. Loose-Fill Insulation

Loose-fill insulation refers to the material which is not in a standard packaged form. Any material like mineral wool, cellulose, rock wool, etc., is available in the market in loose form.

To install loose-fill insulation, all you need to do is cut a stud in the wall where windows and doors will be installed. Further, fill the loose material in that cavity.

4. Batt-Insulating Materials

These are also obtainable in the form of blanket rolls; however, bat insulating rolls have a greater thickness than materials of the blanket type. The installation is also similar to that of the blanket. These can also be stretched across the ceilings or walls of the room.

5. Insulating Boards

Insulating boards are a blend of nature and technology. The pulp of wood, cane, or other materials is pressed very firmly with some force at an appropriate temperature to make these boards.

On the market, you may find them in various sizes. They have excellent insulation properties, and they also have a nice appearance due to their finished surface. Insulation boards are typically used as internal wall lining as well as for use in the construction of partition walls.

6. Reflective Sheet Materials

Sheet materials that are reflective include aluminum sheets, gypsum boards, and steel sheeting. The materials will have a lower emission rate and a higher reflectivity.

Therefore, these materials can withstand high temperatures very well. Therefore, they are very commonly used in industrial applications alongside blanket insulation.

When solar energy strikes and is reflected, there is a reduction in the amount of heat. These are installed on the exterior of the building to prevent heat from entering the structure.

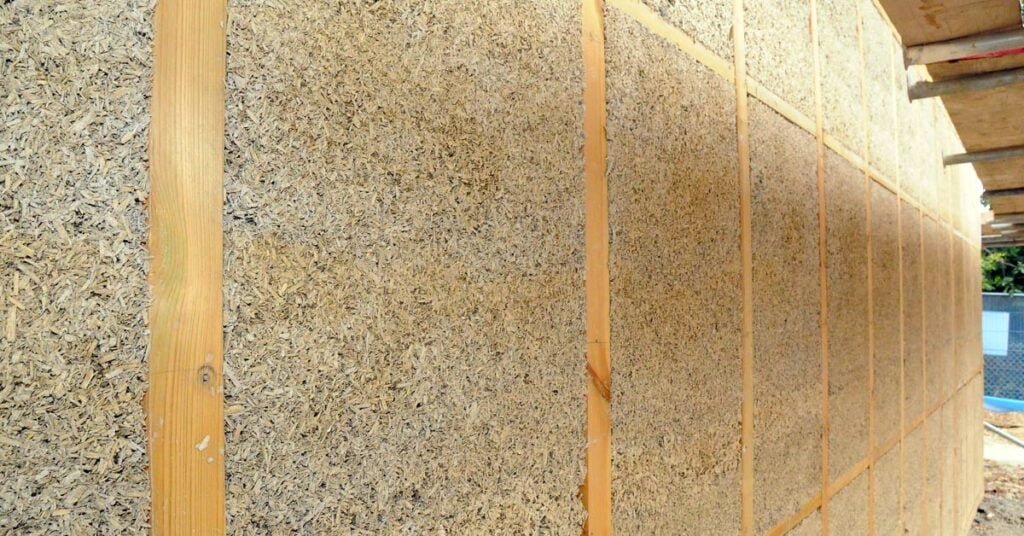

7. Structural Insulated Panels (SIP)

Structural insulated panels or SIPs are prefabricated insulated structural elements made using foam board, liquid foam insulation core, and straw core insulation.

A SIP consists of 4- 8 inch thick foam board insulation sandwiched between two oriented strand board (OSB) sheets or other structural facing materials. They are used in building walls, floors, ceilings, and roofs of a house.

SIPs provide superior and uniform thermal insulation compared to traditional construction methods, offering 12% to 14% energy savings. SIPs have not only high R-values but also high strength to weight ratios.

8. Lightweight Materials

When producing concrete mixture, employing low-weight aggregates will yield good results in preventing heat loss. These outcomes will also be beneficial.

When concrete is constructed with lightweight aggregates like blast furnace slag, vermiculite, burnt clay aggregates, and other similar materials, the concrete will have a greater resilience to heat.

Popular Thermal Insulation Materials

1. Fiberglass

The weaving of very thin strands of glass produces fiberglass, one of the most widely used insulating materials. Fiberglass is made from recycled glass, sand, soda ash, limestone, and other minerals. Fiberglass must contain at least 35% recycled glass to be considered “green.”

R-values can range from R-11 for material that is 3 inches thick up to R-38 for material that is 12 inches thick. The typical R-values of fiberglass are 2.8 to 3.8 per inch of material thickness.

2. Mineral Wool

Mineral wool can be made from either rock wool, which is produced from basalt or diabase, or slag wool, which is produced from blast furnace slag derived from steel mills.

It comprises recycled materials from post-industrial sources in an average amount of 75%. Due to the manufacturing from recycled material, it is environment friendly.

It doesn’t need additives to make it fire-resistant. It is incombustible, and neither it melts. However, it is not suggested for use in extremely high temperatures. The value of its R-factor ranges from R-2.8 to R-3.5 per inch thickness.

3. Cellulose

Recycled paper goods, primarily newspapers, are used to produce cellulose. The recycled material content is up to 85%. It is a material frequently used in blow-in insulation applications and is low-cost loose-fill insulation.

Because cellulose is a densely packed material that has almost little oxygen in it, it is an excellent material when it comes to withstanding the heat and flames of a fire.

In contrast to the benefits, cellulose has some severe downsides. It is dangerous for people allergic to paper dust. Also, it shrinks over time hence its efficiency reduces.

Another issue is the availability of skilled labor to work with cellulose Cellulose has an R-value that ranges from 3.1 to 3.8 for every inch of its thickness.

4. Polyurethane Foam

Polyurethane foam is a lightweight and waterproof material applied with a spray gun. It is an excellent material for filling the spaces surrounding pipes and breaking into minute cracks.

Polyurethane foam is one of the most effective types of insulation; nevertheless, the installation expenses for this type of insulation are higher than those for fiberglass or cellulose.

It has a low cost but is not recyclable and hence not sustainable. Another disadvantage of polyurethane form is its’ flammability. Polyurethane foam has an R-value of 6.3 for every inch of its thickness.

5. Polystyrene

It is available in three forms-

Molded Expanded Polystyrene, often known as MEPS, is a material that is frequently used in the production of foam boards and microscopic foam beads.

Expanded polystyrene, also known as EPS, is composed of small plastic beads that have been melted together.

Styrofoam is the common name for a material called extruded polystyrene, which is a molten polymer that is squeezed into sheets.

Polystyrene has an R-value ranging from 4 to 5.3 for every inch of its thickness.

So these were different types of thermal insulation materials. I hope you now have enough knowledge about it. If you have any questions let me know in the comments.

Comments are closed.