A tensile membrane structure is a construction of elements carrying only tension and no compression or bending. These structures are supported by some form of compression or bending elements, such as masts, compression rings or beams. A tensile membrane structure is most often used as a roof, as they can economically and attractively span large distances.

Tensile membrane structures may also be used as complete buildings, with a few common applications such as sports facilities, warehousing and storage buildings, and exhibition venues Owners and developers across the globe have discovered the advantages of building with tensile fabric building structures as opposed to traditional building products. Whether you are looking for an entertainment venue such as an amphitheater, walkway coverage for travelers at transit stations, or a structure to make your athletic fields suitable for year-round competition, a tensile fabric building structure may be the ideal solution.

Choosing the membrane for your tensioned fabric structure shouldn’t simply be about cost. It should be about aligning project goals with the material’s performance. After all, the membrane contributes to the structural integrity of the project; plays an integral role in functional aspects and defines the project’s aesthetic because it’s the most visible element. Here are some of the properties you should consider when choosing the best-suited tensile membrane for your project.

Features of Tensile membrane

Elasticity – Similar to strength but not the same, elasticity refers to the membrane’s ability to withstand stretching without tearing. The combination of strength and elasticity plays a major role in the distance a membrane can span without additional support.

Durability – Playing a major role in a tensioned fabric structure’s lifespan, the membrane’s durability refers to its ability to resist UV degradation, decomposing organic matter, wind and rain, and other environmental factors.

Light Transmission – A membrane’s light transmission refers to its capacity for absorbing and reflecting natural light. This will ultimately affect the aesthetic and energy behavior inside the structure. Light transmission becomes especially important when designing Tensile Facades.

Fire Resistance – Membranes used in public spaces often need to adhere to certain fire safety codes, including those used in tensioned fabric structures. The membrane’s fire resistance is an essential consideration when choosing a material that’s best-suited for your project’s requirements.

Strength – The area of the visual membrane structure, pre-stress, etc. to select the appropriate technical parameters of the film material, so that the membrane structure material can meet the needs of membrane structure construction and will not cause waste.

Categories of Tensile Membranes in Construction Systems

Tensile membranes can be broadly classified into three main categories within the realm of tensile construction systems: membrane-tensioned structures, mesh-tensioned structures, and pneumatic structures. The first category involves constructions where a membrane is supported by cables, facilitating the distribution of tensile stresses across its structure. The second category encompasses structures where a network of cables bears the inherent forces, transmitting them to distinct elements such as sheets of glass or wood. In the third category, a protective membrane is upheld through the application of air pressure.

Material selection of tensile membrane

The selection of membrane material is important to the successful design of the tensioned fabric structure. The material contributes to the structural function of the system, as well as other important properties involving durability, insulation, light transmission and fire protection. Also, the membrane component of the structure determines the long term appearance of the structure for it is the most visible element of the structure.

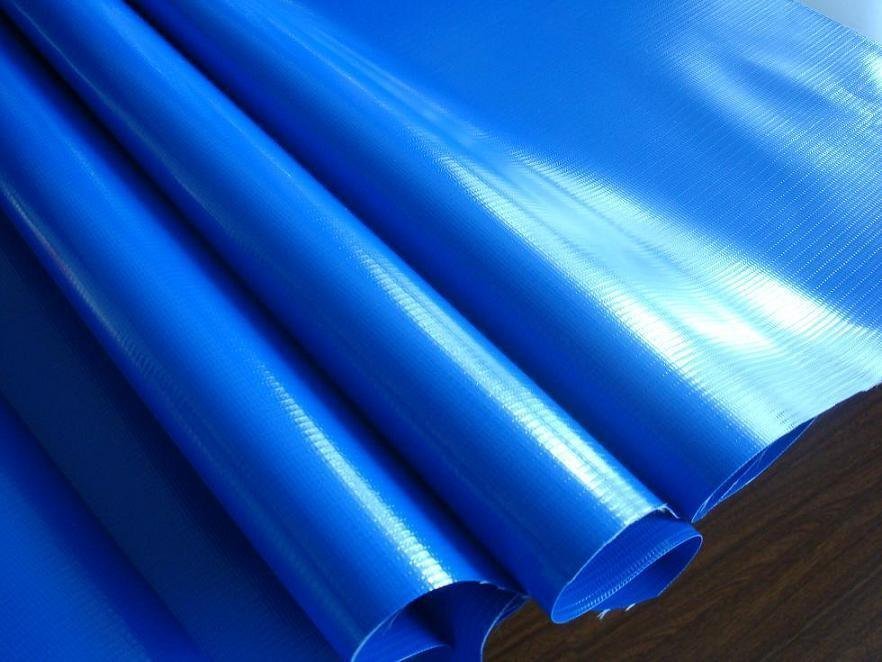

Currently, glass and polyester laminates, composites and fluoroplastic films are most popular. When selecting a membrane, the most important qualities to consider are the mechanical tensile strength and the elastic properties. Due to this, 90% of all weatherproof tensile fabric structure projects have used the following three specific membrane materials: Polytetrafluorethylene (PTFE), polyvinyl chloride (PVC) and ethylene tetrafluoroethylene (ETFE).

These materials are preferable in tensile fabric structures for an array of reasons. Not only do they have the structural ability to support such structures, but these materials have also been in use for years and therefore behavior data of these materials are abundant. These materials have become standardized and therefore the ease of acquiring and designing for these materials are higher than others.

Exploring Popular Types of Tensile Fibers for Fabric Structures:

- PVC Coated Polyester:

- Attributes: PVC coated polyester stands out as a versatile material suitable for both temporary and permanent tensile fabric structures.

- Characteristics: Recognized for its outstanding strength, flexibility, translucency, and cost-effectiveness in comparison to PTFE coated glass cloth and ETFE.

- Coating Benefits: The PVC coating applied to polyester includes UV stabilizers, fire-retardant additives, and anti-fungicides.

- Longevity: PVC coated polyester fabrics boast a structural lifespan exceeding 20 years, making them a durable choice for various applications.

- PTFE Coated Glass Cloth:

- Origin: Developed by DuPont in the 1960s, PTFE coated glass cloth has been integral to the creation of tensile fabric structures since the early 1970s.

- Durability: Originally designed for a lifespan of 25 years, this material has surpassed expectations, with current projections ranging from 30 to 50 years.

- ETFE:

- Film Alternative: ETFE, although a film rather than a fabric, is noteworthy due to its increasing use as an alternative to structural glass.

- Key Feature: Particularly suitable when thermal insulation is a crucial consideration for your project.

- Growing Applications: Rapidly expanding in its applications, ETFE is gaining popularity for its diverse uses in construction projects.

These types of tensile fibers offer unique advantages, catering to a range of requirements in fabric structures, and their selection depends on specific project needs and priorities.

Exploring the Varieties of Tensile Structures

- Linear Tensile Structures:

- Definition: Linear tensile structures are characterized by members experiencing linear tensile forces, where compression members provide support, but the primary load-bearing role is carried by tensile members.

- Example: An illustrative instance is found in cable-suspended bridges, where the primary load is borne by tensioned cables despite the presence of compression pillars.

- Three-dimensional Tensile Structures:

- Description: Three-dimensional tensile structures involve elements primarily subjected to tension, with compression forces directed towards a central mast and subsequently transferred into the ground.

- Common Application: Prominent examples of three-dimensional tension structures are observed in sports arenas, where they often serve as expansive roofs for these architectural marvels.

- Surface-Stressed Tensile Structures:

- Characteristics: Surface-stressed tensile structures share similarities with other tensile types, but their distinctive feature lies in tension-bearing surface members.

- Illustration: Fabric tensile structures serve as exemplary instances, where vertical pillars support specially designed tensioned fabric, showcasing the principles of surface-stressed tensile architecture.

These three types of tensile structures each offer unique design principles and applications, catering to diverse architectural needs. The distinction lies in the distribution of forces, whether linear, three-dimensional, or surface-stressed, influencing the structural integrity and aesthetic appeal of the final construction.

Exploring the Advantages of Tensile Structures

Owners and developers worldwide are increasingly recognizing the myriad benefits offered by tensile fabric building structures over traditional construction methods. Whether creating an amphitheater, providing walkway coverage for transit stations, or ensuring year-round usability of athletic fields, tensile fabric structures emerge as an ideal solution. Here are some of the notable advantages associated with these innovative structures:

- Efficient Construction:

- Methodology: Tension membrane structures, when constructed by design-build specialty contractors, often boast faster and more cost-effective installation compared to traditional building projects.

- Natural Daylight Enhancement:

- Translucency: The majority of fabric options used in tensile fabric building structures offer translucency, allowing abundant natural daylight to filter through, creating an inviting and comfortable space below.

- Weather Resistance and Lightness:

- Modern Fabrics: Tensile structures, made from modern fabrics, exhibit superior weather resistance, lightweight characteristics, and enhanced features like protection from UV radiation and increased wind resistance.

- Design Flexibility:

- Flexible Membrane: The unique flexibility of fabric membranes allows architects and designers to experiment with forms, resulting in visually captivating and iconic structures.

- Cost-Effective Long Span Solutions:

- Light Weight: The light weight of tensile membrane structures proves cost-effective for covering large areas, requiring fewer structural steel supports compared to traditional buildings, ultimately reducing project costs.

- Minimal Structural Steel Utilization:

- Weight Considerations: The minimal weight of the membrane translates to reduced usage of structural steel. This not only diminishes overall costs but also provides more usable space devoid of columns.

- Seismic Resistance:

- Accelerations Under Seismic Action: Due to its minimal weight, tensile structures experience lesser acceleration forces under seismic action, contributing to enhanced seismic resistance.

- Temperature Resilience:

- Material Durability: The membrane material exhibits remarkable durability within a temperature range of -40°C to +70°C. Warranty coverage and a minimum lifespan of approximately 25 years further underscore the resilience of these structures.

- Rapid Construction Period:

- Quick Erection: Tensile structures can be erected in less than a week, with patterning and fabrication predominantly conducted in warehouses. Advanced construction equipment and techniques further minimize the construction period.

The amalgamation of these advantages positions tensile structures as not just innovative architectural solutions but also as economically viable and environmentally sustainable alternatives to conventional building methods.

Membrane structures offer unparalleled design flexibility, allowing for the creation of structures in any desired shape or form. Designers have the freedom to experiment with various shapes, providing an extra dimension of creativity. The membrane fabric used in these structures can be integrated with artificial lighting, adding an additional aesthetic dimension to the overall design. Beyond being a cost-effective solution, tensile structures are aesthetically pleasing, introducing a modern and visually appealing element to architectural landscapes. This concept, although relatively new to the Indian construction scene, is rapidly gaining popularity, surpassing conventional structures in several key areas.