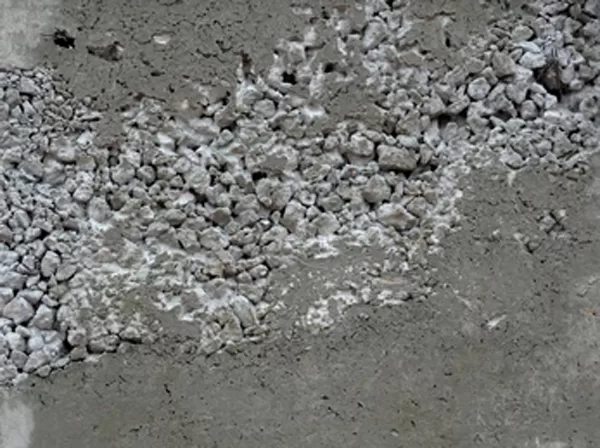

Honeycomb in concrete refers to the presence of cavities and voids on the surface or within the concrete structure. The term “ho[neycomb” is aptly used because the pattern resembles that of a bee nest.

Surface honeycomb becomes apparent when the formwork is removed, whereas internal honeycombs require advanced techniques such as ultrasonic tests for detection.

The existence of a honeycomb structure in concrete poses a significant challenge in construction. It not only diminishes the strength of the concrete but also renders the structural reinforcement susceptible to water and moisture, leading to corrosion of the reinforcement bars.

Corrosion is a detrimental process that weakens the bond between the reinforcement bars and the concrete, posing serious threats to the structure’s longevity.

When honeycomb in concrete occurs, coarse aggregates become visible on the surface, with inadequate bonding of mortar, creating cavities and voids.

Honeycomb is commonly found in columns and beams, occasionally appearing on slabs due to concrete bleeding. To prevent honeycomb formation, proper vibration techniques must be employed in beams and columns during the construction process. Addressing honeycomb issues promptly is crucial for maintaining the structural integrity and durability of the concrete construction.

11 Factors that leads to the formation of Honeycomb in Concrete

It is imperative to know the factors that leads to formation of honeycomb in concrete. Here are the 11 most common reasons that leads to honeycomb in a well looking concrete structure:

- Improper Mix Design Ratio:

Honeycomb may result from an incorrect mix design ratio, emphasizing the importance of precise proportions of ingredients in the concrete mix. - Inadequate Workability Supervision:

Poor supervision of concrete workability during the mixing process can contribute to the occurrence of honeycomb. - Mismanagement of Vibration Process:

Improper management of the vibration process during casting can lead to severe honeycomb formation in the structure. - Issues with Clear Cover Management:

Insufficient attention to managing the clear cover during the placement of formwork can result in honeycomb defects. - Improper Aggregates Grading:

Honeycomb in concrete is likely to occur when there is a lack of proper grading of aggregates in the concrete mix. - Excess or Insufficient Water Usage:

Both excess and insufficient use of water, in comparison to the water-cement ratio, can cause honeycomb. Excess water washes away fine aggregates and cement, while insufficient water affects proper mix cohesion. - Wooden Formwork with Gaps:

The use of wooden formwork with improperly closed joints or gaps can contribute to honeycomb formation, particularly due to concrete bleeding. - Incomplete Settling Time:

Inadequate settling time during casting, where concrete is not poured gradually, can lead to honeycomb issues. - Excessive Coarse Aggregates:

An abundance of large coarse aggregates in the mix makes it challenging for smaller particles to penetrate, resulting in honeycomb formation. - Over Reinforcement:

The use of excessive reinforcement can also be a contributing factor to the occurrence of honeycomb. - Excessive Pouring Height:

Pouring concrete from a height exceeding the recommended level can contribute to honeycomb issues during the casting process.

Classification of Honeycomb in Concrete Based on Size

- Small-Sized Honeycomb

- Medium-Sized Honeycomb

- Large-Sized Honeycomb

8 ways for successfully fixing Honeycomb in Concrete

Here are the 8 ways with which can help you in fixing honeycomb in concrete. Choose what works best for your concrete type

- Limit Freefall of Concrete:

- Ensure that the freefall of concrete is kept under 1.5 meters to prevent segregation and achieve proper consolidation.

- Optimize Concrete Mix Workability:

- Utilize a concrete mix with suitable workability to facilitate proper placement and compaction.

- Fine Aggregate Particle Use:

- Employ a concrete mix with an appropriate fine aggregate particle size to seal the voids between coarse aggregates effectively.

- Adequate Compaction and Placement:

- Ensure thorough compaction and proper placement of concrete to prevent segregation and achieve a dense, uniform structure.

- Rigid and Watertight Formwork:

- Use formwork that is rigid, watertight, and properly sealed to prevent any penetration for fixing honeycomb in concrete.

- Careful Concrete Placement at Junctions:

- Exercise caution when placing concrete at junctions, such as columns and beams. Prefer a concrete mix and down aggregate, ensuring an adequate water-cement ratio to deter honeycomb formation.

- Tapping and Vibration Techniques:

- Tap the formwork from its outer side using a wooden hammer during concrete placement and employ vibration techniques. This helps in preventing honeycomb, especially in critical areas like column and beam junctions.

- Needle Vibrators for Complex Places:

- For fixing honeycomb in concrete of complex areas like beams and columns, use small-sized needles in conjunction with a vibrator during concreting to prevent the occurrence of honeycomb.

Restoration of Honeycomb Issues in Concrete

In cases where honeycombs are identified in concrete, it is imperative to take decisive action. The affected area should be carefully broken, and subsequent re-concreting is recommended, following the application of grouting chemicals on the old surface. Honeycombs, viewed as defects, not only compromise load-bearing capacity but also provide a pathway for water to reach reinforcement rods, initiating rusting and corrosion. The corrosive process continues even in well-constructed concrete, leading to a weakened bond between rods and concrete, posing significant safety risks and jeopardizing the longevity of concrete structures.

Reinforced concrete structures have experienced failures within a mere 20 to 30 years of construction due to honeycombing, which is significantly less than their anticipated lifespan. Particularly in critical areas such as columns, machine foundations, rafts, and beams, where structural integrity is paramount, breaking and recasting emerges as the optimal solution. When honeycombs appear on the surface, pressure grouting with non-shrinkable cement-based chemicals can be considered, subject to the advice of the designer.

It is essential to note that contractors and supervisors may sometimes attempt to conceal honeycombs by superficially applying cement plaster. Site engineers must exercise caution and vigilance in this regard. In areas where columns and beams intersect, concrete with down aggregates should be employed, along with a slightly increased water-cement ratio to mitigate the risk of honeycombs.

Practices such as tapping the sides of shuttering from the outside during concreting and employing vibration techniques play a pivotal role in minimizing honeycomb formation, especially in columns and beams. The use of thinner needles in conjunction with a vibrator at intricate concreting locations also proves effective in reducing the likelihood of honeycombs.

Conclusion: Honeycomb structure in Concrete

Addressing honeycomb issues in concrete is crucial for ensuring structural integrity and durability. Recognizing causes and implementing preventive measures, such as careful concrete placement and formwork management, is key. Swift action, including breaking and re-concreting with grouting chemicals, is essential when honeycomb is detected. Neglecting these issues can compromise load-bearing capacity and the lifespan of structures, emphasizing the importance of proactive strategies and vigilant site supervision, especially in critical areas like columns and beams.”